Mini Risers, due to their high exothermic features have much more feeding capacities compared to the Exothermic Feeders. Mini Risers are used in iron and steel casting and they are approximately 60-70% more productive compared to the Exothermic Feeders. Mini Risers, thanks to their unique structures can be used in production of the small and tight casting pieces where Exothermic Feeders can not be used easily.

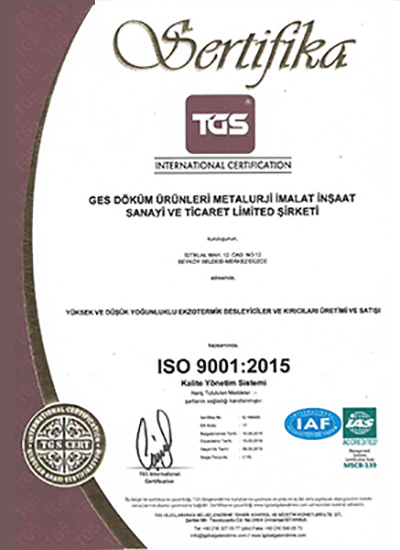

The exothermic feeder sleeves produced by GES are used in iron and steel castings. Many different model Exothermic Feeders are being produced in GES. Apart from the standart production in various measures and shapes, Exothermic Feeders also can be produced upon the special requests of the customers in a short time.

During the casting process a coating powder named EXOPOWDER01 is produced that prevents shrinkages, provides high isolation by forming thin crust on the hot metal preventing fast cooling that expands by engaging in an instant reaction with the hot metal and that is applied on the feeder during the casting process.